OSHA’s Top 10 List of Citations for 2018

Written by: Virginia McCormick, NES, Inc.

OSHA’s top 10 list of violations for 2018 has been released, with one newcomer.

OSHA’s Top 10 of 2018 Sheds Insight on Common Violations

Federal OSHA’s top 10 list of cited violations for 2018 was released in October at the National Safety Council Congress & Expo in Houston, Texas. Federal OSHA publishes the top 10 list annually to, “alert employers about these commonly cited standards so they can take steps to find and fix recognized hazards addressed in these and other standards.”

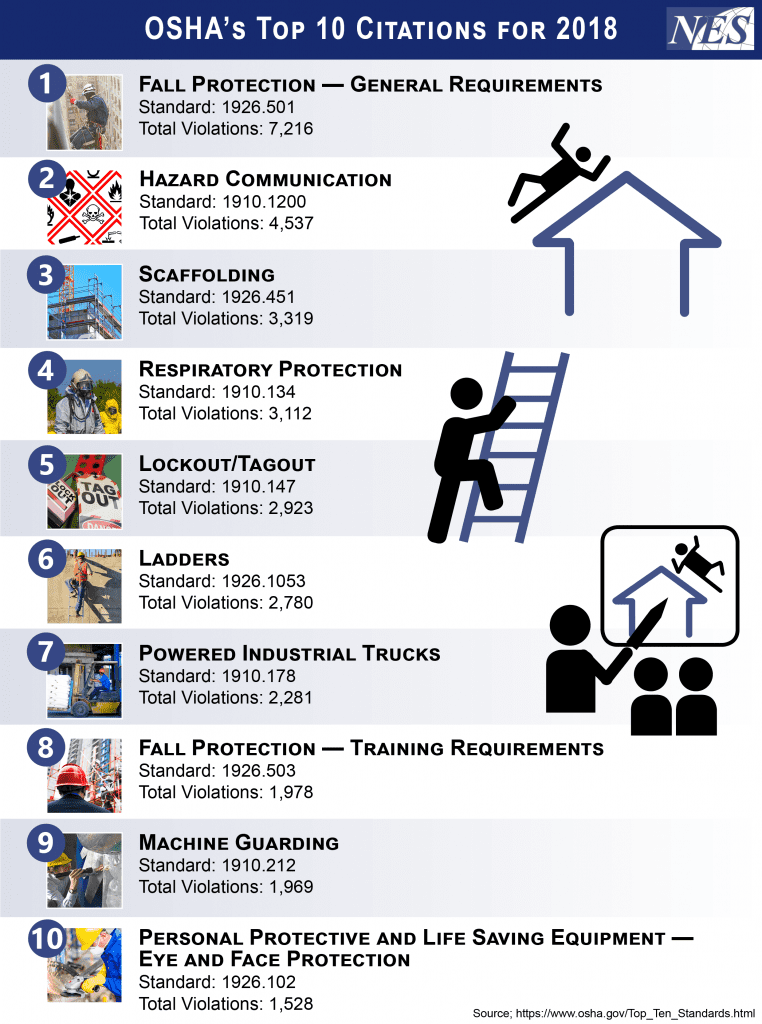

Check out the following NES graphic for a complete listing of the federal OSHA top 10 categories of violations in 2018, including the associated standards and number of citations given.

The above list portrays the federal OSHA regulations and statistics for 2018. The fiscal year ran from October 1, 2017 to September 30, 2018.

Much of the 2018 list is unchanged from the previous year’s list of citations. In fact, the top seven spots have remained the same since 2017, and the top five spots have been the same since 2014.

Compared to 2017, which saw all but one of the categories decrease in cited violations, 2018 seems to have been a mixed bag when it comes to workplace safety. While the arrangement of the list remains similar to past years, the number of cited violations within the ten categories has decreased in some areas and increased in others. Four categories have decreased in number of violations, five have increased, and the final spot was unranked from last year.

With greater emphasis by employers on establishing and maintaining company safety and health programs and on providing regular, job-specific training to employees, we hope to see these citation numbers decrease overall in 2019.

Missed last year’s Top 10 list? For more information, see the NES article OSHA’s Top 10 List of Citations for 2017

Fall Protection Returns, in Both First and Eighth

Once again, Fall Protection – General Requirements (29 CFR 1926.501) topped the list with a total number of 7,270, an increase from last year’s 6,887 violations for the same category. This year marks the eighth consecutive year the category has topped federal OSHA’s list of violations. Falls are one of the most common causes of serious work-related injuries and deaths. As such, fall protection leading the list was expected.

After making an initial debut last year, Fall Protection – Training Requirements (29 CFR 1926.503), with an increase of just over 250 violations compared to 2017, jumped from ninth to eighth. This category is intrinsically tied with Fall Protection – General Requirements, so it’s no surprise to see a jump in both categories.

Employers are required to provide a complete, relevant training program for each employee who might be exposed to fall hazards in the workplace. According to the standard, the program must enable each employee to recognize the hazards of falling and must train each employee on how to minimize these hazards. Fall protection training includes training on the nature of fall hazards, the correct use of fall protection systems, and the role employees play in fall protection plans.

Eye and Face Protection Debuts in Tenth

Eye and Face Protection (29 CFR 1926.102) emerged as the new addition to the list this year, ranking at the tenth spot with 1,536 cited violations. As a subpart of Personal Protective and Life Saving Equipment, the eye and face protection standard addresses personal protective equipment for workers exposed to eye and face hazards.

According to the OSHA overview page on eye and face protection, thousands of employees are blinded each year from work-related injuries that could have been prevented with the proper selection and use of eye and face protection.

Violations in the Eye and Face Protection category can range from protective equipment not being used by workers, to workers not being trained on how to properly wear eye or face protection, to protective equipment not being provided at all by employers. The majority of the 1,536 cited violations came from employers not enforcing the use of appropriate eye or face protection when employees were exposed to hazards, such as flying particles, liquid chemicals, and potentially harmful light radiation.

Fall Protection once again led the 2018 federal OSHA top 10 list of citations, with Eye and Face Protection making a debut in the tenth spot.

Stand-Out Offenders in 2018

Despite the number of violations increasing in some categories for the past year, 2018 saw an overall decrease in penalty dollar amounts for major offenders. In 2017, three alleged offenders were each reported as receiving penalties totaling over $1.5 million, with one offender reaching a staggering total of $2.6 million in willful violations. In comparison, the fiscal year ending in 2018 saw only one alleged offender reach over $1 million in proposed penalties, with the next highest offender coming in at just under $800,000. This information was gathered from OSHA enforcement press releases, located online via the OSHA Newsroom.

Failures to Control Dust and Ignition Sources

A corn milling facility was placed under OSHA’s Severe Violator Enforcement Program after it was cited for 14 violations, totaling a proposed $1,837,861 in fines. This was following an investigation into a May 31, 2017 incident in which an explosion at the milling facility killed five workers and injured 12 others, including a 21-year-old employee who suffered a double leg amputation after being crushed by a railcar. The source of the explosion was suspected to be leakage and accumulation of highly combustible dust paired with uncontrolled ignition sources. The 14 violations comprised eight “willful, per-instance egregious violations” and five serious violations. The serious violations involved fire and explosion hazards, while the other violations included failure to shut down ignition sources, failure to perform required maintenance on operating equipment, and non-implementation of dust accumulation programs.

Failure to Test Atmosphere Before Operations

A group of five contractors was collectively cited a proposed total of $795,254 in fines after an explosion killed three workers and injured two others onboard a towboat. OSHA determined that the explosion occurred while employees performed cutting and welding operations in an area where flammable gases were present. The companies collectively received 55 violations, and one of the five companies was placed in OSHA’s Severe Violator Enforcement Program. The violations included failure to test confined spaces before entry, failure to train workers on confined space operations and chemical container labeling, and allowing hot work / welding operations without prior testing of the atmosphere.

How to Prepare for an Inspection

No employers want their workplace to be unsafe. But sometimes, despite the best of intentions, employers can find themselves on the receiving end of an OSHA violation. The best way to prepare for an OSHA inspection is to seriously dedicate yourself to developing, training, and upholding good workplace practices. However, there are some broad steps that employers and their workers can take in order to prepare for OSHA inspections.

Identify the roles needed for a smooth inspection. Roles may include employee(s) who may greet an inspector upon arrival as well as a company liaison(s) who will check inspector identification cards and notify management. Each role will have specific assigned duties for when an inspection takes place. By identifying these roles well before an inspection takes place, specific duties will become easier to implement and inspections will run smoother.

Know what to expected during an inspection. The Certified Safety and Health Official (CSHO) will often disclose the reason(s) for conducting an inspection during an opening conference. Following the conference is the inspection walk-though, in which the accompanied CSHO tours the facility and documents any observations or citations. The inspector may conduct one-on-one interviews with specific employees. After the walk-though and interviews is a closing conference, which is the opportunity to clarify anything taken into consideration by the inspector. This is the typical structure for an inspection. Knowing the structure for an inspection before one takes place will cause less confusion and fewer problems in general.

Participate in regular hazard training or consulting. Regular training will boost employers’ and their workers’ understanding of what possible violations look like and how to deal with them before an inspection takes place.

Remember, OSHA is not trying to reach goals for violations or penalties given. Rather, the federal agency implements an inspection to ensure standards are being enforced and workplaces are staying safe.

Remember, OSHA is not trying to reach goals for violations or penalties given. Rather, the federal agency implements an inspection to ensure standards are being enforced and workplaces are staying safe.

OSHA’s Top 10 List Highlights Continued Benefit of Training

In a 2018 Q&A with Safety+Health Magazine, deputy director of OSHA’s Directorate of Enforcement Programs, Patrick Kapust, stated that, while the top 10 list is a good starting point, those who are dedicated to finding and fixing workplace hazards should, “take the extra step to find out what’s the most hazardous in your industry and what we [OSHA] are seeing in terms of violations in your particular industry.”

Kapust notes that the OSHA website offers compliance assistance and consultation programs to help employers keep tabs on common violations. Ultimately, there is no substitute for training and consulting that can keep employers and employees safe and off the OSHA violations list.

NES can help your business or agency with its training or consulting needs to help prepare for inspections and to remain in compliance with applicable rules and regulations (view our open enrollment training page by clicking here). For more information about our environmental health & safety training and consulting capabilities, contact NES at 916-353-2360 / 1-800-NES-ADVISE (1-800-637-2384) or office@nesglobal.net.

References:

National Safety Council & Congress Expo Website

OSHA’s Top 10 Most Frequently Cited Standards for Fiscal Year 2018

OSHA Fall Protection – General Requirements Standard (29 CFR 1926.501)

OSHA Fall Protection – Training Requirements Standard (29 CFR 1926.503)

OSHA Eye and Face Protection Standard (29 CFR 1926.102)

OSHA News Release – Region 5: U.S. Department of Labor Proposes Over $1.8 Million in Fines Against a Wisconsin Corn Milling Facility After Fatal Grain Dust Explosion

OSHA News Release – Region 4: U.S. Department of Labor Finds Safety Violations Following Fatal Kentucky Shipyard Towboat Explosion