NIOSH’s Hierarchy of Controls

Written by: Virginia McCormick, NES, Inc.

NIOSH has a variety of programs that help keep workers safe, including the hierarchy of controls.

NIOSH and the Hierarchy of Controls

Poor housekeeping, working at heights, improper extension cord use, and unknown chemicals are all examples of common worksite hazards. Hazards such as these can cause serious injuries or even fatalities if not properly addressed. Worksite hazards can be mitigated in a wide variety of ways, but how do workers or their employers determine which way is the most effective and safe for their circumstances? This is when the NIOSH hierarchy of controls strategy is implemented.

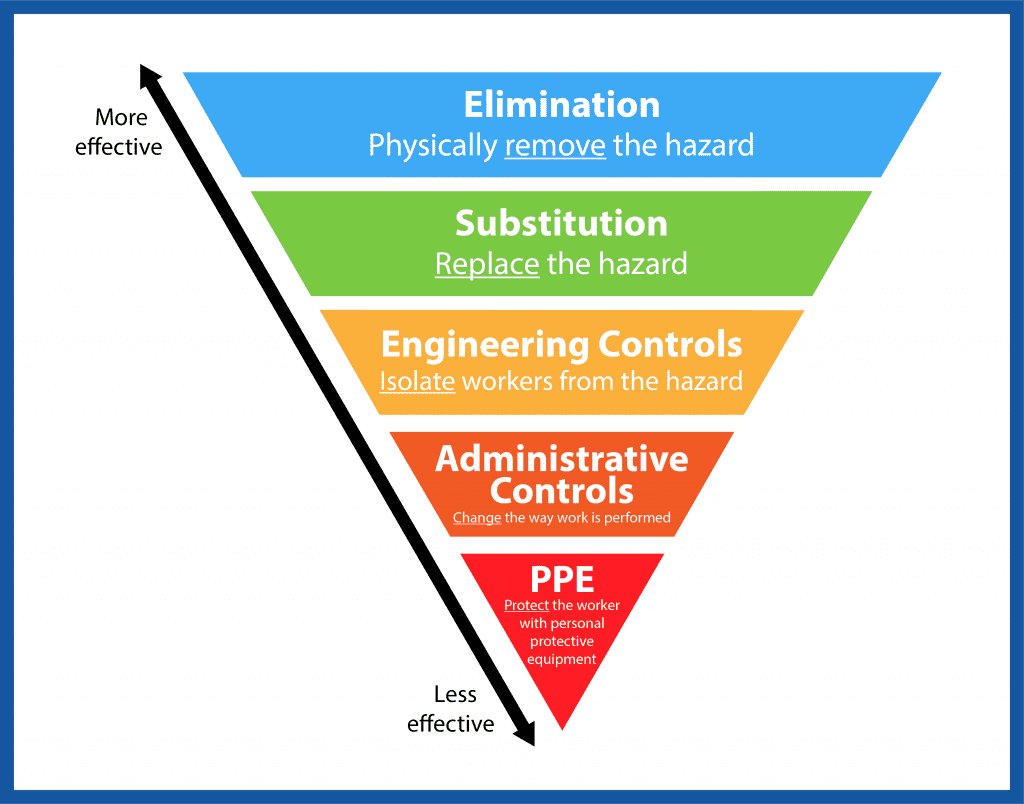

The hierarchy is a strategy that originates from the NIOSH Prevention through Design national initiative to determine how to implement effective hazard control solutions. The hierarchy, commonly depicted as an inverted triangle, is divided into five sections:

- Elimination

- Substitution

- Engineering controls

- Administrative controls

- Personal protective equipment

Understanding and applying the hierarchy of controls helps workers handle hazardous situations effectively.

The control methods on the top of the triangle are considered by NIOSH to be more effective, while the methods at the bottom are considered less effective.

Section One: Elimination

Elimination is physically removing the hazard. It is a straightforward strategy that should be implemented before all other methods and is considered the most effective of the five sections of the hierarchy of controls. According to NIOSH, elimination is the easiest to implement at the design or development stage of a project. Addressing elimination at the start allows designers and planners to make large changes easily without needing to retrofit processes.

Many construction operations involve working at heights. This hazard often cannot be completely avoided; however, certain tasks can be completed at ground level or workers can use extending tools from the ground. Having workers perform tasks in these ways rather than working at heights is a common example of elimination.

Elimination may not be feasible for all hazards but should always be considered first. The investment often can be justified by increased worker productivity, efficiency, and safety.

Section Two: Substitution

The next best way to control a hazard is through substitution. Substitution is replacing a material or process with another that is considered to be less hazardous. To be an effective substitute, the new process or material must remove or at least mitigate the hazard.

Like elimination, substitution is most effectively implemented at the early stages of a project. Since they both depend on drastically changing the equipment and procedures of a project, substitution and elimination become more difficult to implement the further along a project is in development.

For example, using water-based paints in place of lead-based paints is a good way of substituting out a potential hazard. Lead paints can cause nervous system and kidney damage, as well as reproductive harm in adults. Water-based paints used in substitution can help reduce such hazards for exposed workers.

Workers can be exposed to a range of occupational hazards. Effective implementation of the hierarchy of controls can protect workers from these hazards.

Section Three: Engineering Controls

Workplace hazards often cannot be eliminated or substituted, especially when a project is further along in development. In this case, the next best option is to implement engineering controls. Engineering controls are used to isolate workers from the hazard. The initial costs of engineering controls can be higher than with some other methods, but the long-term operating costs are frequently lower, and there are often additional cost savings in other areas. These controls do not interfere with worker productivity or personal comfort like personal protective equipment commonly does.

Installing machine guards that shield workers from airborne emissions is an instance of engineering control implementation. This is a highly effective engineering control because it places a physical barrier between workers and the hazard and can be implemented independently of any worker interaction.

Those looking for engineering control ideas are recommended to visit the NIOSH Engineering Controls Database, which has information on engineering control technologies.

Section Four: Administrative Controls

Administrative controls essentially change the way people work. This method limits exposure to the hazard rather than removing it. Because the hazard is still present, this method is considered less effective than the previous three. Although administrative controls can be used to control employee exposure, they are prone to human error and cannot always be relied upon to reduce exposure.

Administrative controls include employee training, signs and warning labels, and procedure changes. A common example of an administrative control is conducting road construction at night when there are fewer drivers on the road. By changing the work practices at the road construction site, worker exposure to hazards can be reduced.

Section Five: Personal Protective Equipment

The final section of the hierarchy is the implementation of personal protective equipment (PPE). This is often the easiest and most common way to mitigate worksite hazards. However, PPE does not eliminate hazards and may result in workers being exposed if the equipment fails.

PPE, as well as administrative controls, may be relatively inexpensive to establish but can be very costly to sustain. These methods for protecting workers have also proven to be less effective than other measures, requiring significant effort on the part of the worker.

PPE includes gloves, hard hats, safety glasses, high-visibility clothing, and other protective garments or equipment. While personal protective equipment has great value, it is not the most desired mechanism in the hierarchy of controls.

Each section of the hierarchy of controls should be considered when determining how to implement solutions.

A Brief History of NIOSH

The National Institute for Occupational Safety and Health, commonly referred to as NIOSH, is a U.S. federal agency that conducts research and promotes safe working through recommendations and collaboration. The institution, which is a part of the U.S. Centers for Disease Control and Prevention (CDC), was established in 1970 at the same time as the Occupational Safety and Health Administration (OSHA). As indicated on the CDC website, NIOSH works to, “assure every man and woman in the Nation safe and healthful working conditions and to preserve our human resources.”

The hierarchy is one of many safety-focused strategies developed by NIOSH and originates from NIOSH’s Prevention through Design initiative. The initiative’s purpose is to, “prevent or reduce occupational injuries, illnesses, and fatalities through the inclusion of prevention considerations in all designs that impact workers.” Eliminating hazards, redesigning processes, and/or implementing preventative measures to control worksite hazards are some core methods of Prevention through Design that are shared with the hierarchy of controls strategy.

While the hierarchy of controls lists strategies in order of effectiveness, all five methods of control should be considered, as they often work best in combination. Training workers on identifying potential hazards and the proper control methods to deal with those hazards is the best way to promote safety at a worksite.

NES Occupational Health and Safety Services

NES has been providing occupational health and safety training and construction safety oversight services on behalf of a wide array of public and private businesses and government agencies for the past 30 years. For more information on how we can help you manage the health and safety of your employees, please contact NES at 916-353-2360 / 1-800-NES-ADVISE (1-800-637-2384) or office@nesglobal.net.

References:

OSHA: Commonly Used Statistics

Centers for Disease Control and Prevention: Hierarchy of Controls

Centers for Disease Control and Prevention: Prevention through Design

EPA: Protect Your Family from Exposures to Lead

NIOSH: Engineering Controls Database

Interactive Learning Paradigms Inc.: Administrative Controls

NIOSH: Personal Protective Equipment